Lately we’ve been seeing a few MVHR manufacturers offering “free” MVHR ductwork designs with their product sales. If you’re planning an MVHR system in 2022 for your build project you will have likely been offered or found a free MVHR design service yourself.

At Heat, Space and Light we charge for our MVHR detailed ductwork designs, and this articles aims to explain why we charge, how we feel we add value to the service, and the risks involved in free MVHR designs.

Manufacturers don’t offer a full range of products

At Heat, Space and Light Ltd we draw from at least five different suppliers for our MVHR systems in order to purchase the highest performance versions of each item.

We have a steel supplier for our bespoke manifolds, a ducting supplier for our airtight insulated ductwork, roof cowl suppliers, insulation suppliers and of course, Passivhaus Institute-certified MVHR unit suppliers.

We even have specialist room valve suppliers to offer more ornate, decorative and minimalist room valves and diffuser grilles.

If a manufacturer creates a free MVHR design for you it stands to reason they will use only their products in the materials list.

For the main parts such as the MVHR unit, ducting and valves, this will likely be fine, but MVHR systems also require sheet metal materials such as manifolds and ductwork, or insulation products for the environmental ducts. Most MVHR manufacturers don’t have a huge range of products – they focus on their areas of expertise.

If the manufacturer preparing the free MVHR design doesn’t sell a broad array of products, they won’t include them, or will substitute inferior versions. This will result in an inferior MVHR system, and risk that some of the parts will be of lower quality.

Sometimes MVHR installers will neglect to include any sound attenuator drums on the main legs from the MVHR unit to the manifolds – perhaps because they don’t sell them directly, or they’d have to go to a rival.

We include three high performance attenuators as standard even though our MVHR units are the quietest on the market.

We source them from a bespoke supplier, separate to the other MVHR suppliers. It costs more, but we recognise that they are vital to an ultra-quiet MVHR system.

Here’s a video of how our radial ductwork fits into a room plenum, with the socket and valve the only visible pieces from the room itself.

MVHR designs should take time and consideration

All of our MVHR detailed ductwork designs are bespoke because very rarely are two houses the same. This means each design by our team is started from scratch – flow-rates and air velocities have to be calculated, duct routes have to be mapped and valve placements have to be agreed.

Even semi-detached properties which are mirror images of one another may have necessary adaptations.

For all designs, re-drafts may have to be completed, and the MVHR unit and its associated ducting has to be designed in a space-efficient way.

This takes time and expertise. At Heat, Space and Light we organise at least one video call with our clients to discuss the design layout from both a functional and an aesthetic perspective, and the drafting process and ventilation calculations will take one to three days to complete. That’s why we charge what we feel is a fair price for our MVHR designs.

At the end of the process we’re confident the design will work in reality – and that’s crucial.

If a product is free but it costs the company money in time, there has to be a catch. We have a theory that the cost to create the design is “hidden” elsewhere by artificially increasing the price of materials, or lowering material quality but charging a high price.

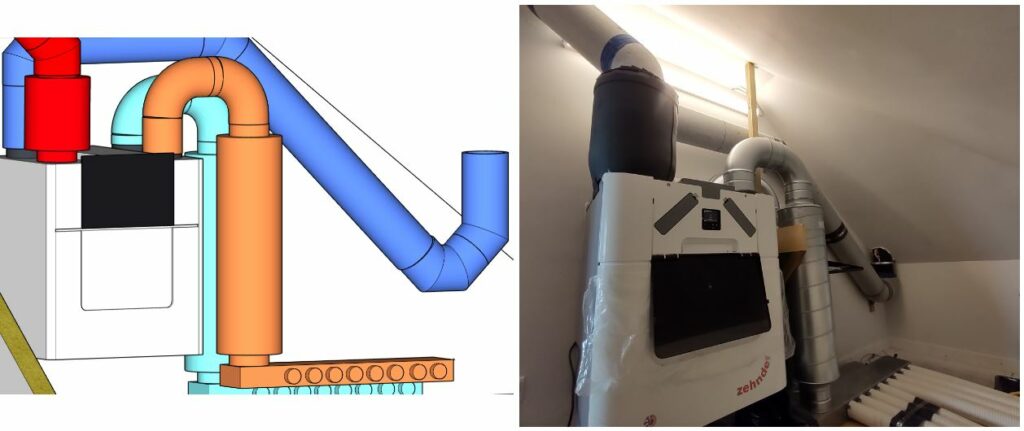

One way manufacturers rush the design is by specifying flexible ducting for the tricky joints around the unit, as otherwise they’d have to take time to design the rigid ductwork properly.

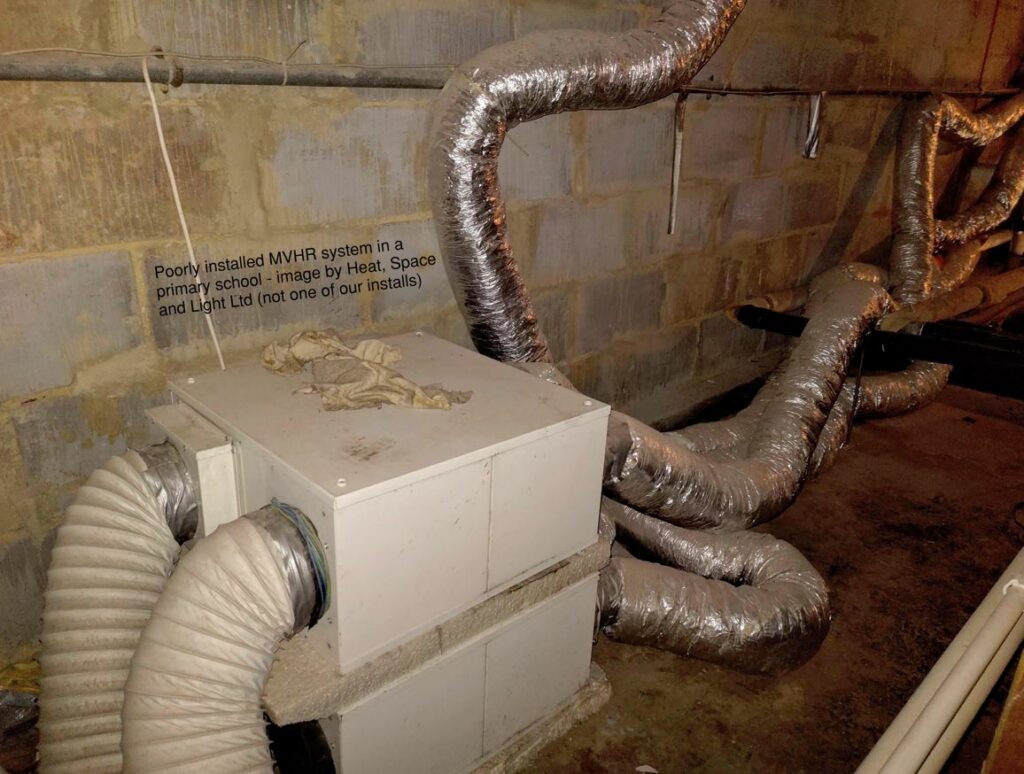

The problem with flexible ducting is that it attracts grime and it’s fragile, so it tears easily. At HSL Ltd we have banned it from our design as it causes such significant performance issues.

To do this we design the 3D of the ductwork around the MVHR unit separately, to ensure the rigid ductwork works for the space.

Mistakes are costly if an MVHR design is rushed

The alternative theory is that the manufacturer rushes the free design to save money. This is dangerous for the home-owner, because if a steel beam is missed and a duct is drawn to run through it (we’ve seen this), on site it will have to be cut or diverted – both expensive mistakes.

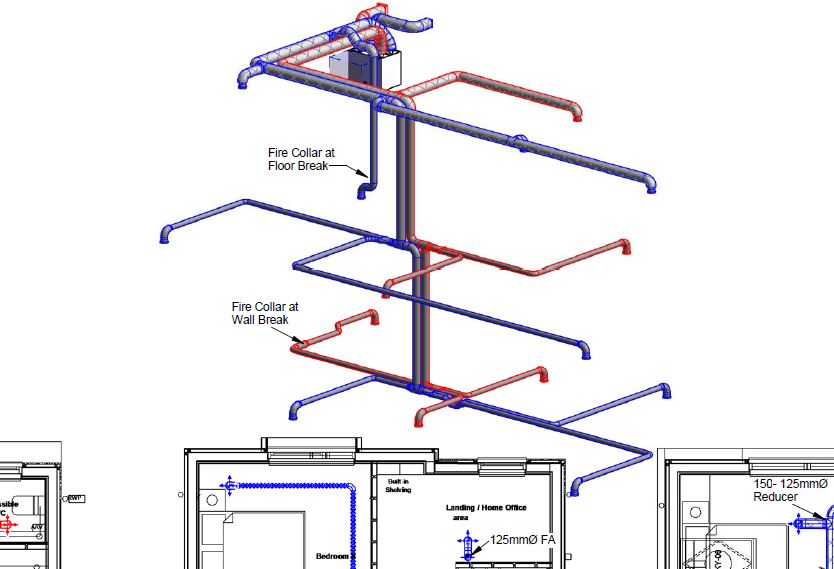

Here’s a screenshot of a 3D design that was sent to us by a confused homeowner.

The 3D appears professional, but the problem was that there was no top floor ceiling to mount all of those ducts – the ceilings were all open vaulted, so none of those upper ducts would fit.

This design by a “free” manufacturer was quite literally useless.

The design also included an MVHR supply valve in a hallway. For a three-storey building this is a protected escape route in case of fire, so a supply valve would be non-compliant here (and not necessary anyway).

Some examples of issues we’ve seen with rushed designs by other companies that have passed our desks include ducts crossing through one another.

Again, this is because it is a rushed free design that on site would cause a headache that will cost more money and potentially force the client to lower their ceiling to accommodate both ducts.

Will the free design include commissioning, balancing and handover?

Commissioning of the MVHR system involves balancing the airflow rates at the room valves to ensure the airflow rates in the design are matched to the requirements.

Balancing is a crucial step because initially when the unit is turned on, air will follow the path of least resistance and flow to the closest rooms to the unit. If you have a bathroom far from the unit, it may not receive the airflow it requires without balancing, and this could result in condensation or mould growth.

Our team uses calibrated measuring equipment to balance the system as part of our commissioning service, and it typically takes 2 to 5 hours on site to balance and lock the system.

Manufacturers may have office staff to complete the free MVHR design, but not on-site staff to complete the commissioning process. Designing an MVHR system without also commissioning it is the equivalent of selling an untuned piano – it may look good initially, but the MVHR simply won’t work properly and may even break eventually.

It’s vital that the designer of your system also commissions the MVHR system to ensure there is no performance gap. If you hire a separate commissioning technician they may get it wrong, or want to commission it their way – and errors can then occur.

Some MVHR manufacturers argue their units can self-commission – this is literally impossible. What they mean is that one can set the flow-rate speeds, but ultimately, to meet Building Regulations’ requirements, the valves have to be adjusted correctly and locked off permanently.

MVHR designs should represent good value

As with most things in life, nothing comes for free. A free design has to either make its money somewhere else in the process, or is so rushed it can’t be accurate.

We think we offer real value that can save money long term in producing an MVHR detailed design that is efficient, super-quiet and ensures healthy indoor air using long-lasting and robust materials.

If you’d like for us to design the MVHR system please contact us via the Contact page, or submit your plans to the free MVHR sizing form and we’ll send you a no-obligation quotation bespoke to your project.

1 thought on “Are free MVHR designs any good?”