When you have decided to specify a Mechanical Ventilation with Heat Recovery (MVHR) system for your home, it can quickly become confusing which type of ducting to use.

There are two main types of MVHR ducting to choose from, explained below:

MVHR ventilation ducting in a “branch” layout

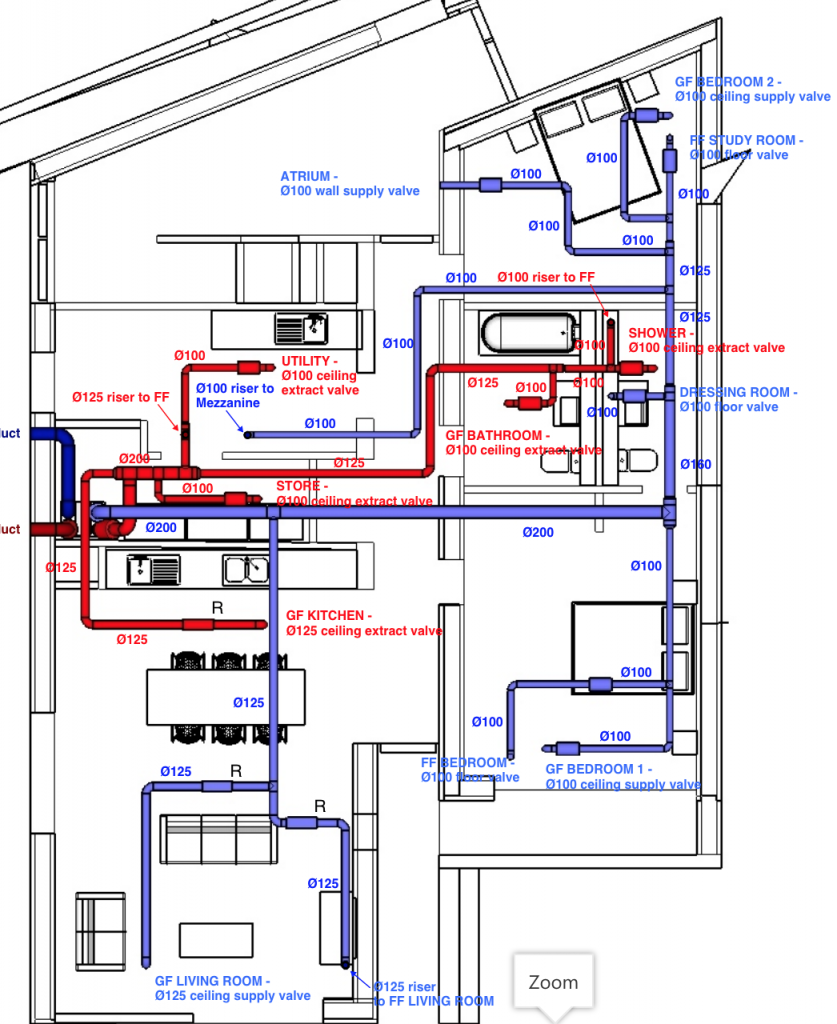

This is the classic ventilation system, also used in commercial buildings such as offices, schools and supermarkets. Ducts, normally made of steel, begin with a large diameter from the MVHR unit, and run around the property “branching” off into smaller ducts as they duct air to each room. Rigid steel ducts will start at between 200mm – 125mm diameter at the MVHR unit, gradually reducing to 125mm and 100mm diameter ducts to each room.

Here’s an example MVHR branch design:

Because ducts branch to different rooms from a single main duct, it’s necessary to place large drum sound attenuators at each room valve to prevent the risk of “cross talk”, because otherwise you could hear people talking through the ducts from one room to the other.

Branch systems require a lot of ceiling, wall or floor space to run the heavily-sized ducts. The sound attenuators are also quite large, although “slim” versions are available – for an extra price.

MVHR systems in a radial or “octopus” duct layout

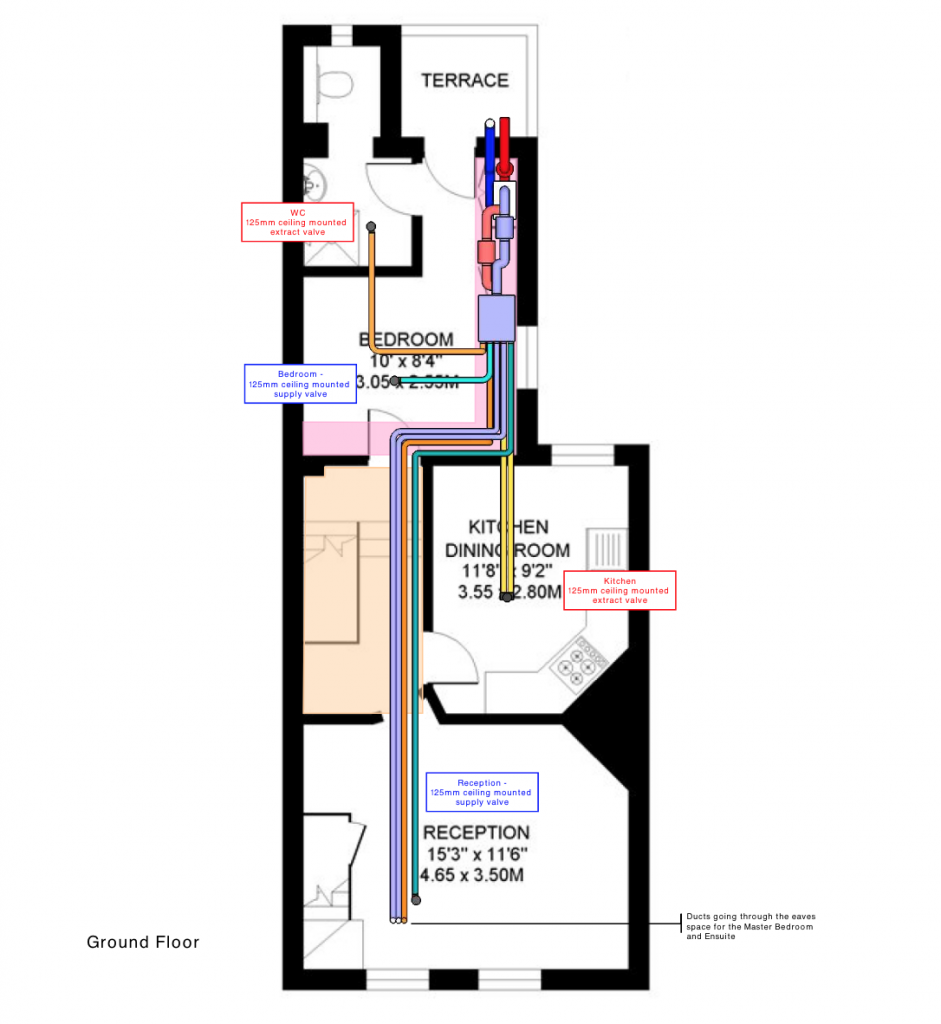

MVHR systems in a radial format have a single (or sometimes two) ducts that run to each room valve from a manifold above the MVHR unit. The ducts are semi-rigid plastic manufactured in 50 metre lengths, so a continuous sealed duct from unit to valve. This produces more ducts altogether, but they are smaller than in a branch system at 75mm external diameter. This means that – at most – any necessary ceiling voids will be only 75mm.

Here’s an MVHR radial duct layout:

Radial systems negate the need for acoustic attenuation at each room valve to prevent cross-talk, because each valve returns to the manifold, which in itself attenuates sound.

Because radial layouts use semi-rigid plastic ducting there is no need for hot cutting works (eg, cutting steel ducts with an angle grinder) and there is very little heavy lifting.

A radial system generally uses less space than rigid steel ducting – apart from above the unit at the point where all of the ducts meet with the manifold (the “octopus” part).

Rigid steel ducting is still used in a radial system for the ducts from the unit to the two extract/supply manifolds, and to and from the exhaust/intake ducts. These ducts also have drum silencers to stop breakout noise from the fan.

MVHR Radial systems are much easier to install than branch layouts

Radial ducting will be much easier to install for a local builder or self-builder. Approximately 50% of our company’s clients in the last few years have self-installed their radial ducting system, and all of them have mentioned how straightforward it was (with our supporting guidance documents). It requires almost no cutting with a circular saw or heavy lifting of steel ducts. Radial is semi-rigid and double-walled, and it’s cut with a common Stanley knife and push-fit into the plenums.

Radial is a single length, so there will be no breaches or leaks and no need to tape the joins between steel ducts (time-saving). This means they’re guaranteed airtight from MVHR unit to room valve. Branch ducts have lots of joins between lengths of steel ducts. If not taped properly they can form air leaks. Any leaks in the ducts will mean the fans have to work harder, wasting energy.

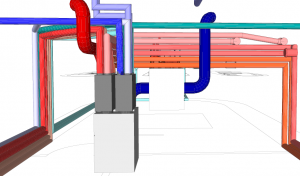

Look at how easy it is to connect a radial duct into a central manifold:

In all of our radial layout installations we’ve seen the design flow-rates met, with very little pressure loss (a common misguided criticism of radial ducting systems is that they can’t supply air to the furthest rooms – we’ve proven this incorrect on many of our MVHR projects).

Radial MVHR duct systems are cheaper than branch layouts

We’ve found that radial system materials are about 30% cheaper than the equivalent branch systems, because steel ducting is more expensive. Installation costs are also much cheaper for radial systems because it’s so easy to cut and fit, as mentioned. If you’d like to receive a free pricing proposal for an MVHR system design and supply for your own retrofit and new build project, please complete the form here with your details, or contact me at Patrick [@] heatspaceandlight.com.

Finally, radial ductwork is easier to clean and maintain long term than branch, because they have smoother bends and longer duct runs for pipe cleaners.

So when should MVHR branch duct layouts be used?

Branch duct layouts are appropriate when the building has lots of rooms which come off a central corridor, for example, student accommodation with lots of bedrooms, or for properties which requires very high flow-rates. They can be appropriate for homes which share a similar layout, but normally the lower cost, ease of installation and smaller ducting of a radial system will “win out” during the detailed design phase of an MVHR system.

It is also used in commercial buildings such as classic ventilation systems, offices, schools and supermarkets. The ducts, usually made of steel, start with a large diameter from the unit and turn into small ducts “branches” around the property as air ducts enter each room. Rigid steel ducts will start at 200mm-125mm diameter in the unit, gradually decreasing to 125mm and 100mm diameter ducts in each room. Is It Possible?

Dear Walter,

Yes, that’s correct – with typical homes the ducting will start at 200mm or 160mm circular diameter and reduce down to 100mm. Keep in mind each 100mm leg will also require a sound drum attenuator between them, which is double the thickness of the duct again.

Best wishes,

Patrick

Performance wise surely the MVHR fans have to work harder to pus air down the semi-rigid ducts?

(Also the large number of octopus tenticals that arrive back at the manifolds does take much more room than any designer will admit to!)

Hi Dave,

In simplest terms, if you have a branch system with a 160mm diameter main duct, at 150m3hr airflow it will have an air velocity of 1.33 m/s. If you have a radial system with 8 to 10 75mm ducts you have the same velocity at 1.33 m/s divided between all radial ducts. Pressure is more complicated than this of course, but the principle is that the overall opening area for each system is the same. That’s before we get into the sweeping bends that radial ductwork can perform against the hard bends of a branch system.

Radial ductwork is most complicated at the manifolds, but once it’s connected into the manifolds it’s very neat – some images of an installed radial manifold here with 90mm ducting: https://www.heatspaceandlight.com/semi-rigid-radial-mvhr-duct-installation-london-retrofit/

Best wishes,

Patrick

What software was used to do the duct work drawings?

This is interesting, thanks. I can also understand how this is easier to balance provided the static pressures at each outlet of the terminal are roughly the same.

However, how does this work for, say, a whole house when some rooms may be significantly further from the manifold than others? Surely this will not be well balanced?

Hi Chris,

Yes, the system still needs to be balanced and commissioned even with a radial system because there will be valves which are out of balance due to varying bends and length.

This is what our commissioning team does when we commission using a calibrated airflow measuring kit: we measure each valve’s airflow rates on arrival with all valves open equally, adjust as necessary and lock each valve against tampering once set.

If you have an MVHR project you’d like us to design, supply and commission a high performance MVHR system for, please submit your plans at the top of the page or contact us directly.

Best wishes,

Patrick