If you’re researching installing a Mechanical Ventilation with Heat Recovery (MVHR) system for your project, you may have heard of an Enthalpy heat exchanger or ERV (Energy Recovery Ventilation).

But what is an “Enthalpy” heat exchanger? How does it change humidity in the home? And is it expensive to install?

The basics of enthalpy heat exchangers

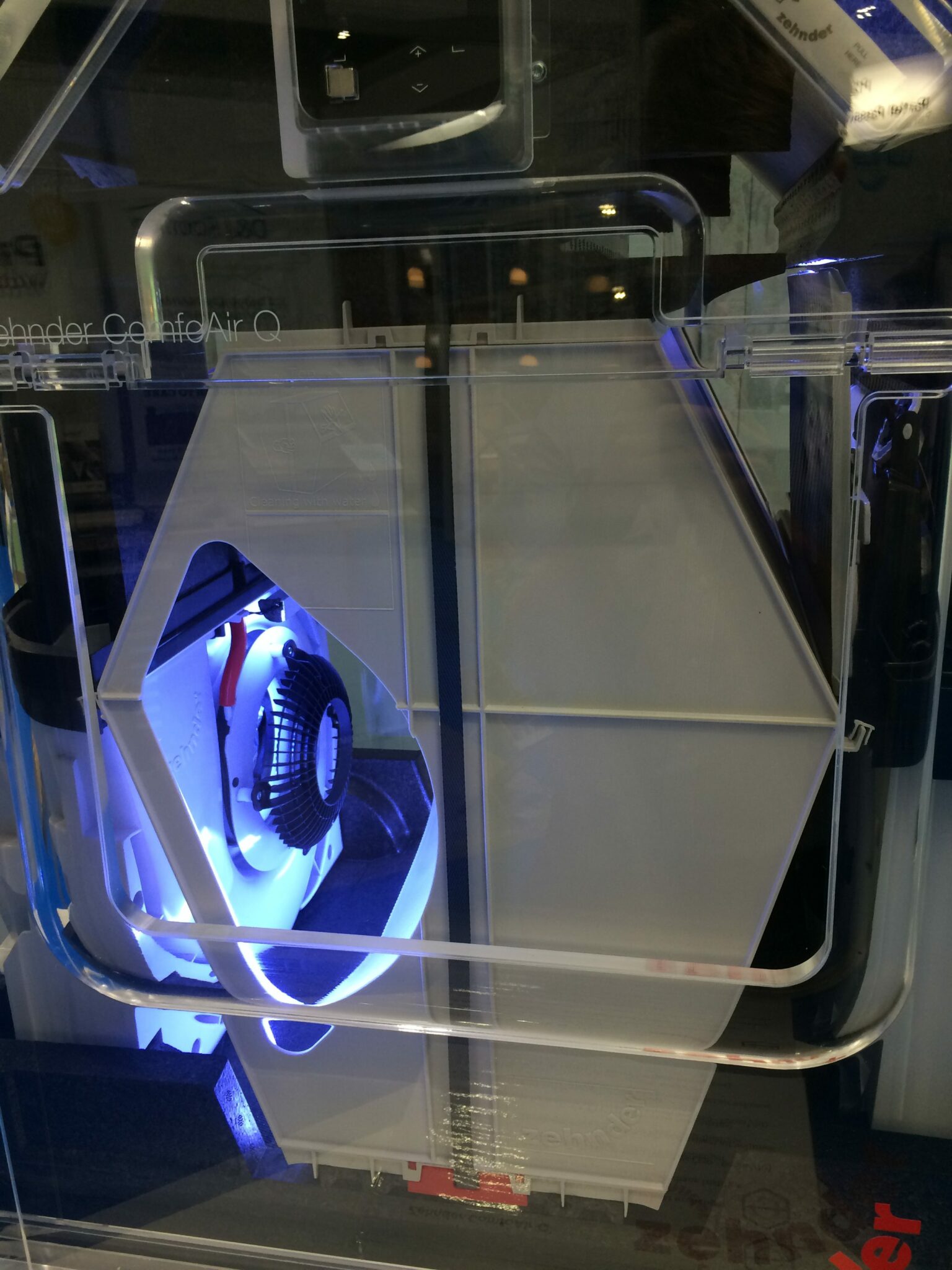

A standard MVHR has a diamond-shaped core made up of thousands of little sections that allow air to flow next to one another. This is where the useful process of moving the heat from the stale outgoing air to the filtered supply air happens.

The stale and fresh air never mixes because the little sections are made of plastic, copper, aluminium or similar. Any water vapour in the air that condenses as it moves from warm to cold air is drained out of a condensate trap below the MVHR unit. This is why we ask for a plumber to connect the MVHR to a waste water pipe during our design process – to drain that condensation.

An enthalpy heat exchanger is set up in exactly the same way, but instead of solid plastic or copper, the material for the heat exchanger is a polymer which allows for water vapour to transfer over from the warm exhaust air to the fresh supply air. It’s important to note that air still stays separate from mixing: it is only the water vapour that transfers. Water vapour is smaller/lighter than air (why clouds float) and the enthalpy material allows this water vapour to transfer. Smells and small particles do not transfer, according to Zehnder’s Enthalpy Exchanger Datasheet.

Why would an MVHR want to recover moisture from the exhaust air?

Part of a well-designed MVHR’s specification is to monitor and control indoor relative humidity (RH) in the home. As occupants, we are healthiest when the air is not too dry (like on airplanes) and not too damp (like in saunas). Keeping the humidity in a building stable also helps prevent condensation, mould, fabric damage and ensures the space is comfortable, particularly in summer.

The ideal RH value is between 40% and 60%, ideally 50%. With a standard MVHR, although it is removing water vapour with the condensate drain, it’s also being generated again by normal occupant behaviour (cooking, washing, drying clothes, breathing). So a healthy equilibrium is maintained.

A problem can occur in homes which are very large but under-occupied, and for this reason an enthalpy exchanger could be a better solution.

Large properties need a dedicated indoor humidity strategy

When an MVHR system is designed it must meet Building Regulations’ Part F requirements. This calculates the whole house maximum airflow rate based on total floor area, number of wet rooms and number of bedrooms. The problem is that these calculations bear no relation to actual occupancy – you could have four people living in a 500m2 home with massive bedrooms, or eight people living in a 90m2 three bedroom home.

Fewer people in a building will naturally cook, shower and dry clothes less, but if their ventilation system is sized for the floor area, the MVHR will be caught in an increasing cycle of stripping away the little bit of water vapour generated into the condensate drain until the air in the home is overly dry.

When we design an MVHR system, we always discuss the actual expected occupancy, and although we have to abide by the Building Regulations for the maximum airflow rate, we offer control functionality to schedule the airflow rates to match the actual occupancy.

If we have calculated that there is a risk of overly dry air, we would specify an enthalpy exchanger. The good news is that there is only a very small price difference of £150 ex VAT between the enthalpy and the standard heat exchanger. Plus, money is saved not having to employ a plumber to install the condensate drain, and the unit saves space as it can be placed directly on the floor.

Are there any issues with an enthalpy heat exchanger?

Yes, an enthalpy heat exchanger should be carefully specified by a diligent designer, as it has a slightly poorer heat exchanger efficiency. A consideration of excess humidity also needs to be considered, particularly in summer, as high humidity is as bad as low humidity.

Are enthalpy exchangers easy to install?

Yes, they literally switch the diamond core heat exchanger with the enthalpy version. However, they must be ordered with the main unit, otherwise they can be more expensive as the original unit will ship with a pre-heater installed to protect against frost, whereas an enthalpy doesn’t need this pre-heater.

Enthalpy exchangers are only supplied by one company in the UK. If you are interested in specifying an enthalpy heat exchanger for your MVHR project please contact me at Patrick [@] Heatspaceandlight.com, or complete the MVHR design form here.

Hello Patrick

I have been reading your articles and wondered if you would be happy to share your wisdom.

Our house is circa 120yrs old and has sash windows. In a couple of the N facing bedrooms rooms we get horrific condensation on the windows with a small lake on the window ledge every morning. Colder it is the worse it is. We have radiators under the windows in every room and have roller blinds within the windows so no curtains. We have a smart central heating system so the core temperature shouldn’t drop below 18. It happens in the smallest room 9×12 and the biggest room 14×24. Even happens if no one is sleeping there although it’s not as bad.

The sashes all fit well but there is air flow / leakage around them.

I have had quotes to fit double glazed sashes into the existing boxes but the installer has said we will have to have 12mm glazing as our sashes are old and quite narrow 1 1/2 top and 1 3/4 bottom so won’t take the 24/28mm glazed panels. So it will be a lot better but we won’t get true double glazing U values.

Replacing the sash box is a nightmare because the house is tile hung and the boxes are behind the tiles.

Having ready your site I was wondering if individual wall mounted heat exchangers in each room might be a better bet than double glazing the sashes.

Would welcome your reply.

Many thanks

David

Hi David,

If the internal air has a relative humidity of 50%, at 18 DegC the window surfaces/frames would only need to dip below 8-9 DegC for condensation to occur (ie, outside temperature for a sash window with little thermal performance). The roller blinds, if they close tightly to the windows, may also be inhibiting air movement, accentuating condensation.

Improving ventilation may help (as it will better modulate internal humidity and higher humidity means condensation happens more easily), but I think it’s more about the windows, as you’ve noted.

Replacing with slim double sash windows would help improve thermal performance and may raise the internal surface temperature of the windows enough that no more condensation occurs.You could perhaps ask them to use a higher performance noble gas between the glazing panels (krypton rather than argon), which would increase performance (and cost) without increasing frame thickness.

Consider also what the new frames are installed into, as you don’t want to create a cold bridge between the wall and the frame – perhaps replacing the boxes and insulating around them would also help, and allow thicker frames to fit.

The final option is retaining the windows and installing secondary glazing, but it may not solve the problem – the secondary glazing is not airtight so humid air can get behind it.

I hope this helps but let me know if you have any more questions, or contact me directly at info[@]heatspaceandlight.com, removing the brackets.

Best wishes,

Patrick

Hi, I found your website after looking for info on the condensation drain – I’m currently in the process of installing a MVHR system and wondered how much water drains away from the unit? The recommended diameter is 22mm but at the moment there is only space to fit a 15mm to the unit which will be fed into into the waste pipe of the bathroom. will that be enough?

Dear Peter,

Without knowing more about the size or type of MVHR system, I’d tentatively suggest that 15mm will be satisfactory, with a caveat that the amount of water will depend on how humid it is indoors and how cold it is outdoors – the more humid indoors, the more water will dump from the heat exchanger core.

It’s also crucial to use a dry trap rather than a p- or s-trap, as these will dry out in summer and the MVHR will pull in air via the pipe – which you absolutely do not want to happen.

Best wishes,

Patrick

Hi,

I had a long talk with one MVHR supplier based in Scotland specifically about moisture as I wanted clarity on whether MVHR did or did not act as a dehumidifier. I didn’t really understand why the person said “yes, under all circumstances.” and his reasoning, and finding your post reminded me of it.

I’m planning to install a new MVHR system in my house, in coastal west Scotland with high humidity all year round. I want the air entering the house to be as dry as possible, so definitely not an enthalpy type exchanger.

I thought that a regular MVHR system removes moisture from the exhaust air (as it cools down) and that the air coming in has the same moisture as outside. So, if it’s a rainy day in the summer and the inside and outside temperatures are about the same, how can the very moist air coming in leave with even more moisture (especially if no one is at home and making extra water vapour)?

Hi Stephen,

It is very season-dependent. In winter, by taking cold air from outside and warming it up as it comes inside (via the intake) it will dry it out, yes. In summer if it’s warm and humid indoors and outdoors then very little will happen though.

It is possible that by “banking” some lower humidity in winter the building structure itself may absorb some of the moisture in summer, lowering the indoor humidity, but this effect would likely be small.

Ultimately in summer it’s about the MVHR preventing damp air building up within the home to excessively high humidity levels and for prolonged periods when it could cause damp and/or mould. And in summer an MVHR also filters out pollen, removes CO2, VOCs, and other indoor pollutants.

I hope this helps – and if you’d like for us to quote for your MVHR system please send your details over via the tool at the top of the page.

Best wishes,

Patrick