Mechanical Ventilation with Heat Recovery systems (MVHR) are actually very straightforward to install yourself, as long as you’re reasonably handy with a drill and you aren’t afraid of heights. Here’s a step-by-step process for how to install your own MVHR or HRV system, safely, without leaks and saving a lot of money. If you’d like free bespoke pricing for an MVHR for your own home retrofit or new build, please send through your details here and we’ll prepare a pricing proposal for you.

1) Get a good MVHR design

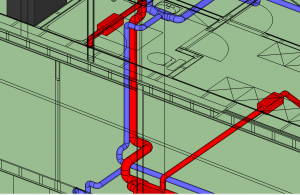

A good MVHR design by a company such as ourselves will work with you to create a ductwork design that doesn’t require boxing in, loss of room space or lowered ceilings everywhere – it is possible to run ducts without negatively impacting space, and I can discuss how with you. Once the design is complete you should be completely comfortable with where the ducts are going, and where the room valves will be placed. We never use flexi-duct in our systems – all of our ducts are 3D-made and solid, designed to the millimetre of spacing.

The ducts immediately around the unit are the thickest, so plan ahead and leave lots of space about the MVHR unit itself. If you use a radial design, the two manifolds are placed above the unit, and they need to be accounted for.

2) Use space wisely

Run the ducting between the rafters or in the wall studs, ideally. It’s good news if you have a suspended ceiling to play around with, too! In a small flat or home, the ducts will be at most 125mm diameter. In a large home they’ll initially be up to 200mm, then branching off to 125mm or 100mm diameter. If you choose a radial design they will be 75mm or 90mm diameter – but remember you will need a duct for each valve in a radial MVHR design, so it can take up more space if you have a lot of rooms compared to a branch design.

4) Consider noise levels

In a radial design, you don’t need attenuators. In a branch design, you do. A good design (by a reputable company) will work out exactly where you need attenuators to keep noise to a minimum. Sound attenuators are thick drums, and they can be twice the size of the ducting, so it’s important they fit right in your design.

5) Future-proof the valves

Find locations for the room valves where bulky furniture won’t block them in the future. In front of windows is a good bet, because you’ll never shove a big wardrobe in front of a window, will you?

6) Limit excessive air resistance

Make sure your design doesn’t have lots of twists or turns. Lots of bends in a ventilation system will create excess air resistance, and this will increase the fan duty – which means more money to run and more noise.

7) Don’t duct through structure

Watch out for structural beams – you can’t notch a steel I-joist like you can do with wall studs or ceiling joists, so you’ll have to go around anything structurally important.

8) Open up the duct spaces

Make sure all of the ceiling areas and walls you want to put the ducting are exposed. Purchase all of your ducting from a reputable supplier – don’t be tempted to buy cheap. Lots of suppliers will sell you spiral rigid steel ducting (as used in industry) but you need it to be rubber-sealed. This will reduce the likelihood of air leaks when you join the ducting.

9) Cut and size on the ground

Lay all of your ducting out. Use an angle grinder to cut it to size on the ground before you raise it in the air. Smooth down the cut edges. You can lay the ducting before you put in the MVHR unit – months in advance if you’re doing other renovation work.

10) Clean your ducting inside out

Clean all of the ducting inside and out, as it can be quite mucky inside. Use a garden hose and wash away the dirt and steel filings. If you don’t do this your MVHR filter will be clogged as soon as you start up the unit.

11) Hang the ducts properly

Use metal strap-banding to support your ducting to the joists or wall studs. You don’t have to use a lot – one strap band per bend or 1m length will suffice. Drill one end of the strap band into the stud or joist, put up the ducting (this might require two people) and drill the other end of the strap band. You want it tight.

12) Use foam to stifle vibrations

If ducting is tight to a wall/floorboard, consider putting a length of foam between the duct and the wall or board. This will stop any vibrations through the duct system.

13) Don’t underestimate the unit ducts

A good design will have considered the ducting around the MVHR system itself. This is normally the most complicated part to connect, as there are four large diameter ducts all going in different directions (one intake from outside, one exhaust to outside, one extract from the house, one supply to the house). Take care when you connect all of this ducting.

14) Plan where the air goes in and out of the house

Consider the two air ducts to and from outside. You need an intake and an exhaust, and they can be anything from 125 to 200mm diameter each. They should be approximately 2m apart so they don’t contaminate each other, but if you don’t have the space you can use a combined grille. The simplest ducting is through a wall, but you can also go through the roof.

15) Buy the best MVHR unit you can afford

Consider your MVHR unit carefully. You need a quiet one, and it’s worth paying the extra money for it. Don’t just agree with what your builder / contractor / plumber wants to throw in, especially if they want to buy a unit off the shelf from a building trade merchant. Consider that this unit will be on CONSTANTLY, so you need one that promises to be almost silent, or at least whisper quiet. Buy a Passivhaus-accredited MVHR unit to be sure from a reputable supplier like ourselves. If you’d like any help, guidance or pricing for your MVHR system, please contact me at patrick [@] heatspaceandlight.com.

16) Ask the professionals if you get stuck

Hopefully, you’re all there, and you and your family have clean, filtered and warm air all through winter – without ever opening a window.

Any questions you might want to ask an accredited installer of MVHR and HRV systems, go right ahead in the comments below and I’ll answer, or email me directly Patrick at Heatspaceandlight.com – replacing at with @.

Do you do designs? If not who would you recommend?

Hi Alan, yes we do detailed ductwork designs for MVHR systems. I will email you from my company address and we can discuss more.

Hello. I’m a plumber & I want to retro fit a MVHR system in my own house. A radial layout with 75mm might suit best. It’s a 2 story house & from the attic I can get to nearly all the rooms via hot press & built in wardrobes etc. Therefore I’d be restricted on the ground floor as to the location of the ceiling vents. The kitchen vent would be directly over the hob. Would this be an issue? I was considering an AquaAir E300. Would that be a good unit?

Hi Alan, this sounds very workable – please could you send plans and/or info to Patrick [at] heatspaceandlight.com (with an @ symbol) and I’d be happy to review the initial design and put forward some system types.

Best wishes,

Patrick

Hi,

can I have your email, please?

I also have some question 😀

Thank you

Hi Daniel, I sent you an email through my work email address, did you receive it?

Hi there, I’m interested in a ductwork design please, if you can drop me an email to understand your process. Thank you

Hi Lucy, I’m on holiday at the moment but if you email Patrick [at] heatspaceandlight.com and mention this blog, one of my colleagues will be in touch right away. Best wishes, Patrick

If the unit is run during the winter only is there any concern re legionella or other bugs?

thanks

Hi Jason, an MVHR system has free-flowing air running through it constantly, so there’s no chance of any standing water- ever. The only water is from the condensate drain, which is linked to a waste water pipe. Do you have a live MVHR project you’re working on? Best wishes, Patrick

should the ducting in an open attic space be insulated or does this not create condensation in the pipe work?

thank you

Hi Maurice,

If the ducts are running in a cold attic space (outside of the thermal envelope) then they need to be properly insulated. The reason for this is not to do with condensation risk, but because the ducts will lose the useful heat they are carrying inside, and the air will become cold before it reaches the heat exchanger.

If you need any help with designing your MVHR system, please email me at patrick [at] heatspaceandlight.com, replacing the [at] with a @ symbol.

Best wishes,

Patrick

I am trying to install a new HRV system in my 40 year old home that wasn’t built to accommodate the ducting required for one of these units. I have most of the ducting completed without demoing walls and moving electrical or plumbing of one form or another.

Scenario I have a bathroom in the center of the house 1 wall ontop of triple floor joist for a starwell, 1 wall with all the fresh water piping for 2 body showers, 1 wall with a pocket door and all its hardware plus an outlet and light switch and the last wall has allot of electrical, central vac and black & grey water piping and waste water vent piping.

Question I have another wall that I can a rigid duct pipe up through to the attic space 10 feet away,

1.- can I run a insulated flex duct through the attic space and connect it to a ceiling grill in the bathroom?

2.- If I can does the ducting have to be buried under the attic insulation or laid on top?

3.- Does it have to be installed sloping towards the rigid duct so if the humid air condenses the water doesn’t pool and weight down the ducting in the lowest point between the two ends?

4.- Besides having the piping sealed to the grill box and the rigid duct the vapor barrier on the outside of the grill box vapor barrier and the ceiling vapor barrier is there and other precautions I have to take?

Hi Brian,

We wouldn’t recommend using any sort of alu-flex ducting, as it tears and crushes so easily, particularly in a loft. I would suggest semi-rigid ducting would be better – it’s strong enough to be stood on, and it’s only 75mm external diameter (you would need two ducts to the bathroom). In answer to your questions:

1. Theoretically you can flexi-duct in a loft, but as mentioned, flexi duct crushes and tears easily, so it’s not recommended.

2. If ducts are in the loft, they should be buried within the insulation, as this would allow it to keep “within the thermal envelope”. The problem you’ll have if you use flexi-duct is that the weight of the insulation will crush it, so you should use semi-rigid ducting instead.

3. The air within the duct is constantly extracting, so there’ll be no chance of any moisture pooling internally within the duct. The condensation risk is actually external for this duct, given it’s in a “cold” roof (although below the insulation layer). A semi-rigid duct wrapped in closed cell insulation would be ideal.

4. As long as all ducting is within the airtight and thermal layer, you should be fine.

Hope this helps. Feel free to send your designs / plans over via email to patrick [@] heatspaceandlight.com if you require.

Hello,

We are building a single storey 3 bedroom house near Obidos in the Leiria district in Portugal. We are looking to install a MVHR system but the architect has no experience of these systems and it seems difficult to find local expertise.

I am happy to pay for professional design etc and is this something you are interested in. Build hasn’t started yet but I wanted to get location of inflow/extract etc early so that we can lock down prices etc.

Do you support Portugal or have an affiliate company we could work with.

Hi Michael,

Thanks for your enquiry. In theory there’s no reason why we can’t prepare a detailed ductwork design for your property. For our design, we produce a full 2D schematic of the detailed ductwork design which accounts for acoustic, efficiency and air velocity calculations. We supply only the highest-quality materials that are best in class for acoustics, summer bypass and controls.

We can ship to Portugal, although international carriage fees may apply. The unit and certain bespoke components I would suggest getting from us, and then the more generic pieces could be locally sourced.

You can appoint my team to install if you’re willing to fly us out and board us (five star or up, please!), otherwise the output of our detailed design is usually enough to allow a local team to do the installation – but we’d still recommend that we commission the system at the end of the project.

I speak conversational Portuguese, coincidentally, although it’s been a few years.

Do intake and extract ducts need to be similar length? Unit has 150mm spigots.

Plan to extract straight up (through roof tile terminal rated at 20,000mm Free air (unit specifies minimum of 12,500mm) probably ~2m

To get an intake from a north wall, the run will be about ~8m total (terminal, 5m straight, swept 90 deg, 1m straight, 45 deg 2-2.5m straight)

Does this sound ok? Other options are:

– locate unit in loft (very short intake/ exercise extract runs)

– intake from south wall (shortest run, 1 90deg bend)

– intake from west wall ( 2 90deg bend, 1 45deg bend, maybe 5m total run)

Hi Andrew,

Intake and exhaust ducts don’t need to be similar length, but with 8m, you’ll need to make sure the duct is very well insulated to prevent any risk of condensation as it’s cold air inside. Hope this helps, but send me an email if you need any more info. patrick [@] heatspaceandlight.com.

Best wishes,

Patrick

Many thank for advice – very much appreciated. Great site 🙂

I should add, to locate in loft would probably require 90 degree bends directly from unit

We’d like to retrofit an MVHR to a 1940s semi-detached, two-storey, three bedroom house, which we intend to add a large kitchen extension to. Who can I speak to about your design services and how you would interface/interact with our chosen architect? Many thanks.

Hi Emma, yes, we can work with your architect on detailed MVHR ductwork layout. Please contact me at info[@]heatspaceandlight.com – removing the [] and I’d be happy to help. Otherwise you can contact me via the form page with details on the home – Free MVHR Sizing Tool Page.

Best wishes,

Patrick

I’m in the process on buying a house and because I’m going to be insulating the full house to make it airtight I am looking into retrofitting a MVHR unit. I am insulating my full loft and turning it into the plant room for the house so ideally Iv planned to install the unit inside the loft as well. I have researched a lot but yet still am in need of further assistance as need to calculate airflows and unit size. Could you please help?

Hi Aaron,

Yes, happy to help. Please either send me the plans through email at Patrick[@]heatspaceandlight.com or via the online MVHR design form here

Best wishes,

Patrick

Hi Patrick,

I now MVHR System design. I have work on mvhr system till five years experience.I want job. If you help please contact me.

Best wishes,

Nihal

I am interested in you designing (confirming) my duct runs. I am currently drawing (trying to) a 3d picture to copy and practice on. Details below.

Hi George,

We’re happy to help. I’ve sent an email from Patrick [@] heatspaceandlight.com – please do send through the plans/sketches and we’ll take a look.

Best wishes,

Patrick

Hi, is it possible to push air into one room and extract it from an adjacent room by allowing the air to flow between the two rooms through oversize vents. Thanks Tony

Hi Tony,

This is how an MVHR system works in normal practice – air is supplied into a living area and the air is gently guided through the door to an adjoining bathroom/kitchen where the air is extracted. A small door undercut allows this to happen even if the door is closed.

If you’d like to discuss an MVHR project in more detail please contact me at the link at the top of the page.

Best wishes,

Patrick

Hi, Patrick, that’s very helpful I may well be back to you when I accumulate more knowledge

Thanks Tony

Hello! Thank you for this fantastic text. Right now I am trying to design a ventilation ducting and I have some doubts. Can we talk via e-mail?

Dear Jose,

Happy to chat – please send me an email.

Best wishes,

Patrick

Hi Patrick, good information… I have a 5 bed house, built 30y ago, looking to retrofit some form of controlled ventilation. The house has 2 open chimneys,1 tradition fireplace, the other with a gas stove. The main issue is that the house is built in a valley, near a river, approx 500 metres downstream from a dam. Hence at certain times the humidity levels outside are high, currently -4c 85% humidity, being on a cloud free night. Which asks the question of the air being drawn wetter than the air it is replacing in a MVHR system.

We suffer from high condensation in occupied bedrooms, unoccupied bedrooms are relatively clear.

1. My question is would we be more suited with an attic installed Warm Air Dehumidifier (WAD)?

2. I can’t see many of these in the UK, but seen one by VapourFlow inline WAD, any experience on such units?.

3. As persons sleeping in a bedroom produce around 1/2 litre of breath moisture, would it be practical to extract from the bedroom with the output feeding into the passageway outside the bedroom door, with the dry air passing under the door?

Thank you in advance…

Hi Peter,

Yes, ultimately, with the right energy efficiency, insulation and airtightness strategy, all homes are candidates for MVHR.

To run through each point:

1) The traditional fireplace would be a source of cold air ingress and also a safety issue in terms of flue gases, so closing it up or converting it to a wood-burning stove would make it compatible with MVHR.

2) Regarding humidity, -4 DegC at 85% relative humidity is only 15% relative humidity at 20 DegC. You can see this on a a psychrometric chart, which presents the physical and thermal properties of moist air in a graphical form.

In practice, what this means is that if you take very humid cold air and warm it up, you dry it out. The air coming in via an MVHR system is warmed up, which lowers the humidity. This is a good thing, and it will mean you will have lower condensation in the home. An MVHR is effectively a natural dehumidifier whilst also ventilating and recovering heat back in during winter to save energy and money.

3) I’ve not seen a WAD before, but compared to an MVHR it’s using about 10x more power to do the same thing that an MVHR does passively (200W compared to 20W).

4) Regarding bedrooms, we need fresh air to breathe as we sleep so we actually supply air to bedrooms. This effectively dilutes the humidity and CO2 in the bedroom, and at the same time this air is pulled via the door to extract points in other (bath)rooms.

I hope this helps. If you’d like to discuss MVHR for your property in more detail please contact us on the page at the top.

Best wishes,

Patrick

Hi Patrick,

I would like to get quotation and basic information for MVHR design of a project located in London.

Please get in contact with me.

Hi Josh,

Best way to receive an MVHR sizing and specification proposal with our design, supply and commissioning services costs is to email us via the Contact Us page, or via the Free MVHR calculator at the top of the page.

Best wishes,

Patrick